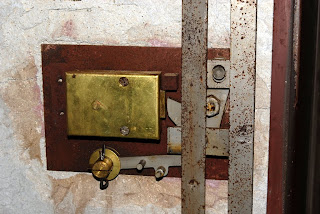

I managed to pick the key lock of the safe using these lock picks. Now it only takes me up to 20 seconds to pick that lock. It seems to be a standard cylinder lock with now extra security. The cylinder rotates a few degrees and then stops. When I now turn the combination dial I can feel the key cylinder changing its rotation angle and the dial rotation is hindered by some friction.

A first analysis of the dial indicates a deep depression between 55 and 59. At the moment I assume this to be the cam gate location. Once the notch drops into this I have to turn the key cylinder slightly back to get out of it.This indicates that the cam gate has steep sides and maybe even the lever nose. If that is true I wont be able to measure the lever nose depth by measuring the cam gate width. Another approach would be to measure the key cylinder rotation angle which should be proportional to the nose depth in the cam gate.

From an expert on the internet I learned that this type of safe typically has fixed flies and the cylinder key lock is essentially the handle.

The fixed flies are much cheaper to manufacture. It essentially means that the safe has two different combinations depending on the initial dialling direction. This slightly complicates the standard approach since direction has to be taken into account. I might need to measure the fly width to get a better understanding of the lock.

The key lock being essentially the handle means that to open the safe one would first dial the correct combination and then turn the key to retract the bolts.

The next step is to set up some good way to measure the cylinder rotation and the graph the nose depth (angle) at the cam gate for different combinations.

More soon...

A first analysis of the dial indicates a deep depression between 55 and 59. At the moment I assume this to be the cam gate location. Once the notch drops into this I have to turn the key cylinder slightly back to get out of it.This indicates that the cam gate has steep sides and maybe even the lever nose. If that is true I wont be able to measure the lever nose depth by measuring the cam gate width. Another approach would be to measure the key cylinder rotation angle which should be proportional to the nose depth in the cam gate.

From an expert on the internet I learned that this type of safe typically has fixed flies and the cylinder key lock is essentially the handle.

The fixed flies are much cheaper to manufacture. It essentially means that the safe has two different combinations depending on the initial dialling direction. This slightly complicates the standard approach since direction has to be taken into account. I might need to measure the fly width to get a better understanding of the lock.

The key lock being essentially the handle means that to open the safe one would first dial the correct combination and then turn the key to retract the bolts.

The next step is to set up some good way to measure the cylinder rotation and the graph the nose depth (angle) at the cam gate for different combinations.

More soon...